The Impact of 3D Printing on Road Cleaning Trucks

Introduction

In today's fast-paced world, technological advancements have transformed various industries, including road cleaning and maintenance. Ceksan Sweepers, a pioneering company in the field, has leveraged the power of 3D printing technology to create highly efficient and innovative road cleaning trucks. In this article, we will delve into the details of how 3D printing has revolutionized the road cleaning industry and why Ceksan Sweepers has become a leading provider of these cutting-edge trucks.

The Role of 3D Printing in Road Cleaning Trucks

3D printing, also known as additive manufacturing, is a process where a three-dimensional object is created by layering successive materials based on a digital model. This technology has gained significant popularity due to its ability to produce complex and customized parts with high precision and accuracy.

Ceksan Sweepers recognized the potential of 3D printing in the road cleaning industry, particularly in the design and manufacturing of road cleaning trucks. By utilizing 3D printing technology, Ceksan Sweepers can develop intricate components that are crucial for the effective performance of these trucks.

Optimized Truck Components

One of the key advantages of 3D printing in road cleaning trucks lies in the ability to optimize the design and functionality of various components. Ceksan Sweepers utilizes this technology to create parts that are lightweight, durable, and specifically tailored to meet the demands of road cleaning operations.

Traditional manufacturing processes often restrict design possibilities and result in heavier components that may affect the overall performance of road cleaning trucks. In contrast, 3D printing allows for the creation of intricate geometries and lighter structures without compromising on strength and durability.

Moreover, by leveraging 3D printing technology, Ceksan Sweepers can customize truck components based on specific requirements, resulting in enhanced efficiency and cost-effectiveness.

Faster Prototyping and Iteration

Another significant benefit of 3D printing technology is its ability to facilitate faster prototyping and iteration processes. Road cleaning trucks require careful engineering and testing to ensure optimal performance and reliability.

With traditional manufacturing methods, prototyping can be a time-consuming and costly endeavor. However, 3D printing enables Ceksan Sweepers to create prototypes rapidly and efficiently. This helps in reducing development cycle times, allowing for more iterations and ultimately leading to improved products.

By embracing 3D printing, Ceksan Sweepers can identify and rectify design flaws early in the product development stage, resulting in road cleaning trucks that exceed industry standards and customer expectations.

The Advantages of Ceksan Sweepers' Road Cleaning Trucks

Ceksan Sweepers' commitment to innovation and excellence has enabled them to design road cleaning trucks that offer unparalleled advantages. By combining the power of 3D printing and extensive industry expertise, Ceksan Sweepers has developed trucks that thrive in tackling the challenges of road maintenance.

Enhanced Efficiency and Performance

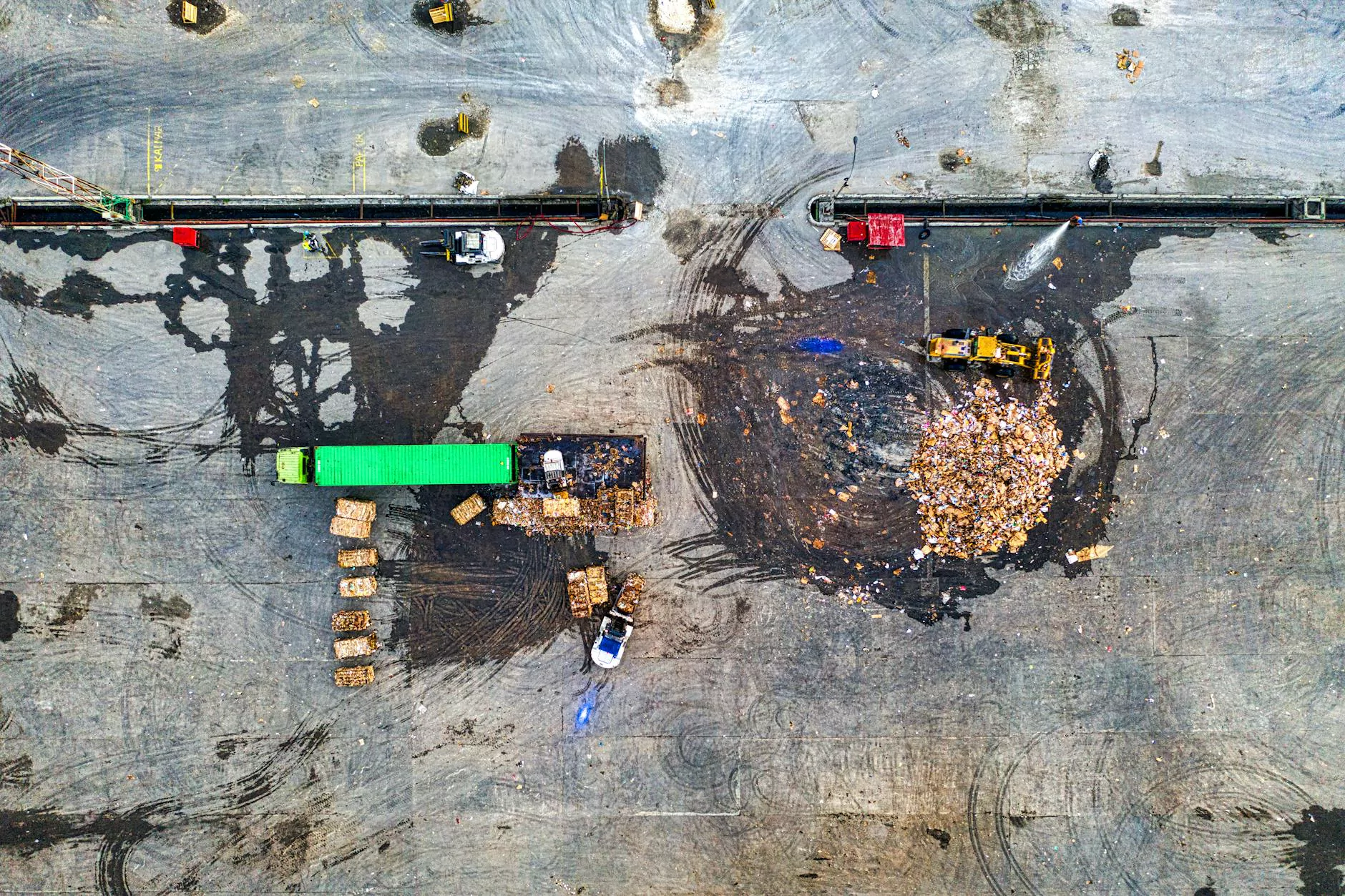

Thanks to 3D printing technology, Ceksan Sweepers' road cleaning trucks are equipped with optimized components that maximize efficiency and performance. The lightweight yet robust parts enable the trucks to operate seamlessly, offering increased maneuverability and reduced energy consumption.

Furthermore, the customization options provided by 3D printing allow Ceksan Sweepers to tailor the trucks to specific cleaning requirements. Whether it's sweeping debris, cleaning up spills, or maintaining highways, their trucks are designed to excel in various road cleaning tasks.

Cost-Effectiveness and Sustainability

3D printing offers significant cost-saving opportunities throughout the production process. By eliminating the need for expensive tooling and reducing material waste, Ceksan Sweepers can deliver road cleaning trucks at competitive prices without compromising on quality.

In addition, the durability and longevity of 3D printed components result in reduced maintenance and replacement costs. The trucks' sustainable design, with its focus on lightweight materials, also contributes to fuel efficiency and environmental responsibility.

Conclusion

The marriage of 3D printing technology and road cleaning trucks has ushered in a new era of efficiency and innovation. Ceksan Sweepers has embraced this technology to develop cutting-edge road cleaning trucks that optimize performance, reduce costs, and promote sustainability.

By utilizing 3D printing, Ceksan Sweepers has proven itself as a frontrunner in the industry, offering superior road cleaning trucks that meet the demands of modern infrastructure maintenance. With their commitment to continuous improvement and technology-driven solutions, Ceksan Sweepers is poised to shape the future of road cleaning.