Understanding Plastic Mould Manufacture

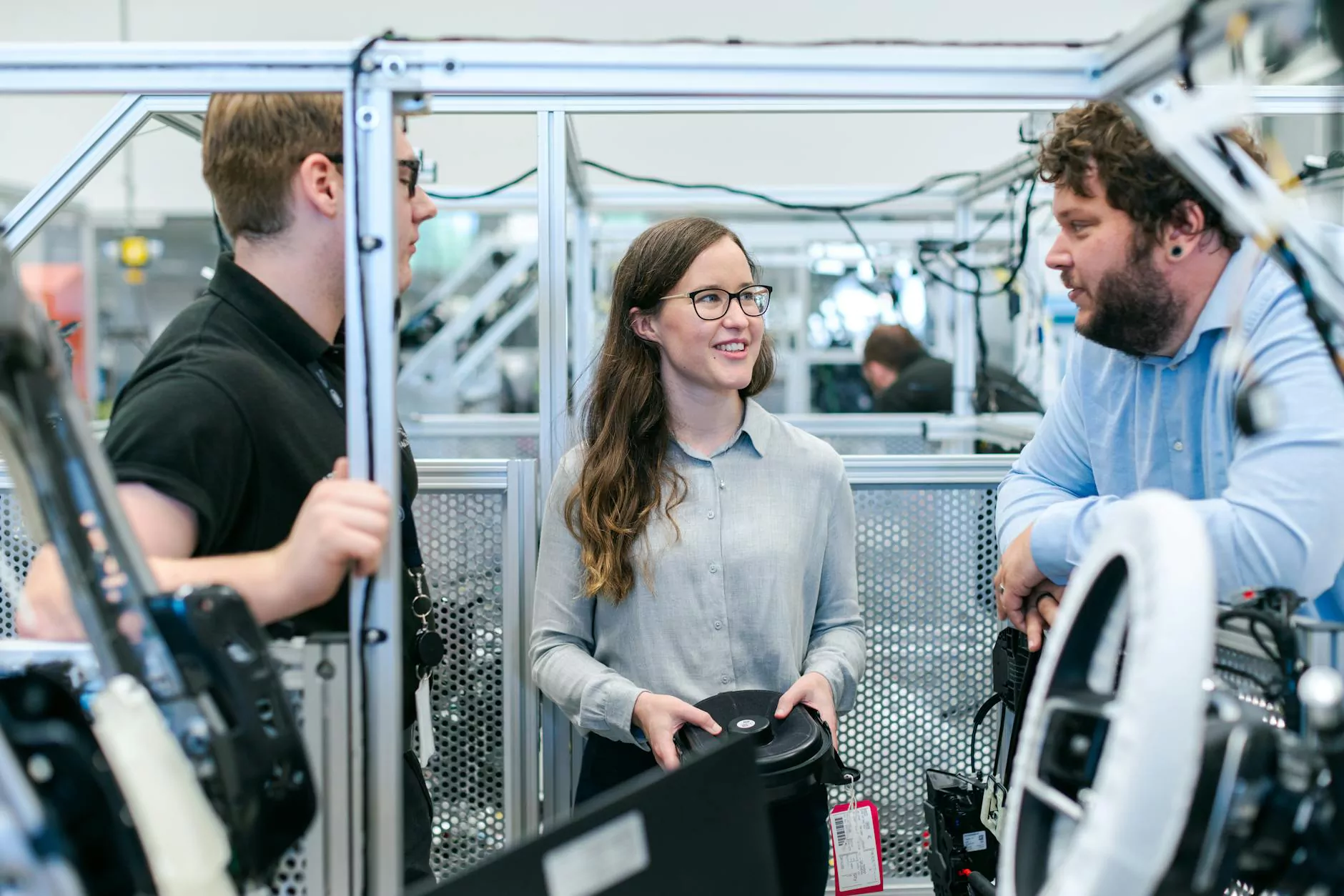

Plastic mould manufacture is a critical component of the modern manufacturing landscape, enabling companies to produce high-quality plastic components efficiently and at scale. In the evolving world of production, understanding the processes and benefits associated with plastic moulds can provide a significant edge to businesses across various sectors.

The Process of Plastic Mould Manufacture

The journey of plastic mould manufacture begins with design and engineering. This stage involves creating a digital representation of the desired product, usually through Computer-Aided Design (CAD) software. Key steps include:

- Concept Development: Collaborating with clients to define product specifications.

- Prototype Creation: Producing a prototype through techniques such as 3D printing or CNC machining.

- Mould Design: Finalizing the design for the mould, ensuring it meets all technical requirements.

Materials Used in Mould Manufacturing

Choosing the right materials for moulds is crucial for the success of any plastic mould manufacture project. Common materials include:

- Steel: Favored for its durability and ability to withstand high temperatures.

- Aluminum: Often used for lower volume production due to its lightweight and cost-effective properties.

- Composite Materials: Providing a balance between durability and weight, suitable for a variety of applications.

Types of Moulds in Plastic Injection Manufacturing

Plastic moulds come in various forms, each tailored to specific production needs:

- Single Cavity Mould: Produces one part per cycle, ideal for low-volume needs.

- Multi-Cavity Mould: Allows for multiple parts to be produced simultaneously, enhancing production efficiency.

- Family Moulds: Capable of producing different parts simultaneously, beneficial for related product lines.

Advantages of Professional Plastic Mould Manufacture

Utilizing professional services like those offered by Hanking Mould comes with a plethora of benefits:

1. Enhanced Production Efficiency

By investing in advanced mould technology, businesses can significantly increase their production rates. High-quality moulds lead to reduced cycle times and less downtime.

2. Superior Quality Products

Professional mould manufacturers employ stringent quality control measures, ensuring that every component produced meets the highest standards.

3. Cost-effectiveness

While the initial investment in mould design and manufacturing may seem substantial, achieving economies of scale through high-volume production can ultimately lead to lower costs per unit.

Applications of Plastic Mould Manufacture

Plastic mould manufacture finds applications across numerous industries, including:

- Automotive: From dashboard components to exterior parts, the automotive sector heavily relies on plastic injection moulding.

- Consumer Electronics: Manufacturing casings and internal components for devices like smartphones and tablets.

- Healthcare: Producing essential medical devices and tools with stringent regulatory requirements.

Sustainability in Plastic Mould Manufacturing

As environmental concerns grow, the plastic mould manufacturing industry is also adapting. Companies like Hanking Mould focus on sustainability by:

- Implementing energy-efficient machinery to reduce energy consumption.

- Utilizing recyclable materials for production.

- Adopting waste-reduction strategies that minimize excess material usage.

Future Trends in Plastic Mould Manufacture

The future of plastic mould manufacture is promising, with several trends shaping the industry:

1. Automation and Smart Manufacturing

Companies are increasingly turning to automated processes powered by Artificial Intelligence (AI) to enhance precision and reduce human error.

2. Additive Manufacturing Integration

Additive manufacturing techniques are beginning to be integrated into the mould-making process, allowing for rapid prototyping and customization.

3. Advanced Materials

The development of new materials with improved properties is expected to drive innovation in mould manufacturing, leading to lighter and stronger products.

Conclusion

In summary, plastic mould manufacture is pivotal for businesses looking to enhance their production capabilities while maintaining high-quality standards. Companies like Hanking Mould stand out as industry leaders by providing expert services in plastic mold making and plastic injection mould manufacturing. By leveraging advanced technologies and adhering to best practices, businesses can not only meet their production goals but exceed customer expectations.

Investing in quality mould manufacture is not just a choice; it's a strategy for long-term success in a competitive marketplace. Embrace the opportunities that come with advancements in plastic moulding and watch your business flourish.